Greetings

Friends in the Name of Safety:

To

quote Sam Cooke, "A change is going to come!"

Safety Section UPDATE: As most of

you know, the Safety Education Section will

institute a fee for services beginning

December 1, 2009. Pamela Young, Chair of

the N.C. Industrial Commission will be making

the announcement within a couple of weeks.

The fee schedule will be announced at that

time. Thanks again for your continued

support!

The Other

News Is... We are still having the NC Zoo,

Asheboro Basic & Advanced APCAP program

October 26-30, 2009 for Basic and October 26

& 27, 2009 for Advanced. This will be the

last one before the fee schedule begins.

The ADVANCED class is FULL, but we still

have a few seats open for the BASIC

class.

To register for the Basic, please

CLICK HERE

80th Statewide Safety

Conference!

Mark your calendar now for

May 11-14,

2010! Eighty Years of Safety and

Counting...

|

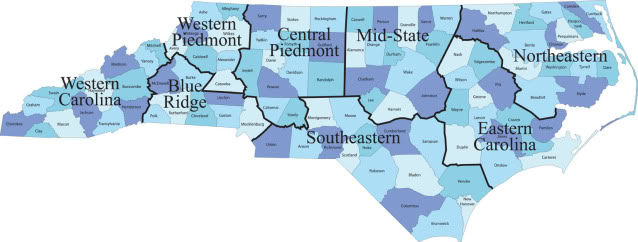

Regional Safety Councils

Please... don't forget to support your

Regional Safety Councils by joining

their membership ranks and participating

in their scheduled events. For

membership applications, see the Quick

Links to the right.

|

The Western Piedmont

Safety Council awarded their Lifesaving

Award to three individuals at it's

August meeting at the Smokey Bountain

Smokehouse & Creamery. Those in the

picture are, from left,

Doug Brookshire - Safety Director

for Bernhardt Furniture and Chairman of

the Western Piedmont Safety Council;

Charlie Steelman - an employee of Tyson

Foods in Wilkesboro; Henry Steelman - an

employee of Louisiana Pacific - Roaring

River; Justin Billings - an employee of

Louisiana Pacific - Roaring River; and

Dennis Parnell - Director of Safety

Education with the North Carolina

Industrial Commission in Raleigh.

Charlie and Henry Steelman received a

Life Saver Award from the Western

Piedmont Safety Council for saving the

life of a man who had fallen out of his

boat on March 23, 2009 on W. Kerr Scott

Reservoir. Justin Billings received a

Life Saver Award for his actions to help

save the life of a woman whose car had

gone into the river in Roaring River, NC

on February 19, 2009.

The Western Piedmont Safety

Council covers 8 counties and is

sponsored by the N.C. Industrial

Commission. The objective of the WPSC is

to promote safety in industry, home, and

public places with special emphasis

placed upon industrial

safety.

If you have a lifesaving experience you

believe would qualify for this award,

please contact your Regional Safety

Council for more information.

|

NCIC Video Library

Due to recent budget requirements,

we will discontinue our video

library on December 1, 2009.

At this time, we are not sure if

this will be permanent or short

term. Once a decision has been made,

we will inform you.

We apologize for any inconvenience.

|

Keep S-A-F-E, Safe!

Remember these four steps

to safety

Prevent accidents on the job by staying

S-A-F-E, which stands for:

Stay alert.

Pay attention to your work. Avoid

becoming complacent or taking shortcuts,

no matter how many times you've done a

job. Be prepared for the unexpected.

Ask questions.

Don't take anything for granted. Check

with your supervisor when you are unsure

about a substance, procedure, or piece

of equipment. If you're not sure if

something is a hazard, ask. If something

seems wrong, but you're not sure what,

ask. Never let a safety question go

unanswered!

Focus on safety

problems.

Take time to look for hazards. Inspect

your work area, tools, equipment, and

materials before you start every job.

Anticipate potential problems and be

prepared to deal with any problems that

arise while you work.

E liminate hazards.

Take responsibility for your safety.

Follow safety rules. Used assigned PPE.

Keep your work area neat and safe.

Remove or repair safety hazards you're

trained to handle, and report the ones

you can't correct to your supervisor.

Make safety an important part of your

job-every minute of every day.

For more information, please give

Dennis a call at 919-218-3000 or email

Dennis.

|

|

My Laptop Bit Me!

By

Michael Nance By

Michael Nance

I must admit,....I am not

as prepared for the monthly newsletter

as I usually am. I sometimes have 3 or 4

newsletter topics going on at the same

time; jotting down comments whenever

possible and even calling my home phone

to leave myself a note about a nifty

quote I heard. I honestly refrain from

trying to drive and write stuff down

while talking on the cell phone. If it's

too detailed, I pull over or ask someone

if I can call back. It's not worth the

risk and chance of getting into an

accident.

Speaking of "risk", how many of you back

up your computer files? I imagine most

of you have someone in the building

taking care of the business materials

and making sure back ups are made daily

and maybe even storing this offsite. You

may not think back up files are made,

but they are. It's just that you can't

get to them unless you're a pro in

hacking computers. Our section has

strived for over 80 years to prevent

accidents. One of those nifty quotes

that popped into my brain last week was:

"An ounce of prevention is worth a pound

of cure." Not sure,...but I know it went

something like that.

At the Nance home, we have three

computers (that work). One is the

regular desktop style that you don't

move. It has the big/bulky CRT monitor

that looks like a TV (I refuse to spend

the money on a flat LCD until the one I

have explodes). It's primarily the PC

(that's "Personal Computer") that the

kids use - games, research, games,

emails, and then some games. The PC

works fine but is years behind

technology. Then my wife has one she

uses for her school work (she's a high

school teacher). She's always doing

lesson plans, checking student homework,

emailing other teachers about meetings,

etc. It's very convenient for her and

allows her to do some work in the

comfort of the home instead of staying

late at school every day. The third PC

is mine. The one I'm using now.

My original laptop decided to take a

trip south without me about three weeks

ago. I lost everything. But wait,

there's more!!!! Yes, I made a backup of

my files; however, I did that about 3

months ago and really hadn't thought of

doing it again. The IT department in

Raleigh told me to bring it in and they

would see what they could do. I was

really hoping I could recover important

documents, safety photos, power points,

etc., but it was not meant to be. The

laptop was "re-imaged", or in my words,

"wiped clean". By the way, we call them

laptops but I rarely see one actually on

a person's lap. I was disappointed but I

knew I had backups at home; six CD's

worth and some memory sticks. Problem

is, the re-imaged laptop would not

recognize the files. Neither would the

backup laptop. Rats!!! Sure, I thought

of other words like "Hamster", "Dang It"

and maybe a few more.

Where is all this going? Simple. Make

back ups of your files now. Tonight when

you get home. Just like someone who is

bypassing a machine guard or another

safety rule, sooner or later it will

bite you back and it will be painful. I

spend hours recreating presentations and

other required files that I must keep.

My brain was like Jell-O several nights

in a row. Even though some photos are

gone and lost forever, I have been able

to find replacements. We have all heard

the phrase, "There is a silver lining in

every cloud", and I guess in my case, it

caused me to do what I had been putting

off. For example; the topic Blood Borne

Pathogens has not changed too much in

the past several years but I get drained

of presenting the same power points over

and over so I usually have 6 to 8

different ones to mix it up. I knew I

needed to redo many of our topics and I

was trying to find the time during

training sessions to do it. The laptop

crash caused me to buckle down after

hours and over the weekends to do just

that; refresh myself with many of the

topics and also refresh the power

points. Like seeing a movie for the

fifth time and noticing things you

didn't see or hear before. It's like an

"Ah-Ha" moment. Or perhaps a cool new

accident prevention idea that will also

save expenses. Then you want to share it

with others, try it out.

The average computer user doesn't think

much about problems that can arise with

a computer until a problem actually does

occur. That sort of sounds like some

upper management folks I used to work

with. Once a failure happens, repairs

can be both costly and time-consuming.

As with a good safety program,

preventive measures are the best tools

to keep things on track! Prevent a

catastrophe and get those files backed

up as soon as possible.

Editor's note: Michael Nance is the NCIC

Blue Ridge, Southern & Western Piedmont

areas Safety Representative. If you are

interested in having one of our programs

in your area, please give Michael a call

at 919-218-9047 or email him at

Michael.Nance@ic.nc.gov

|

If

Only They'd Paid Attention

Why safety meetings and training

are important

One of the best ways

to get the safety information you need to

avoid job accidents is in safety meetings

and training sessions. That's where you'll

learn what you have to know to protect

yourself and your co-workers from workplace

hazards.

Here are some true stories of workers who

probably didn't pay enough attention in

safety meetings and training sessions.

A worker's arm was crushed when he reached

into a conveyor belt mechanism to remove a

blockage. He turned the power off but didn't

lock out the conveyor. A co-worker who

couldn't see him turned the power back on.

An employee died

when he tried to stop a hazardous solvent

spill by turning off a valve instead of

following workplace rules to evacuate. He

wasn't wearing a respirator and was overcome

by toxic vapors.

A worker was

killed when a piece of metal he was cutting

bounced off the table and hit him in the

head. He wasn't wearing a required hard hat.

A worker in a

trench was killed in a cave-in because he

failed to properly shore up the sides.

Two workers were

killed when a crane fell over on them

because a co-worker had loaded the crane

above its rated capacity.

Both workers died

when an employee with no protective

equipmentor safety line tried to help a

co-worker who was overcome by cyanide gas

while cleaning a tank.

One employee died

and one was seriously injured because the

overloaded scaffold they were working on

collapsed, sending them 12 feet to the

ground.

An employee was

killed when she tried to slip past a backing

forklift. The operator didn't see the worker

behind him, and she was crushed between the

forklift and a wall.

If only these workers had paid

more attention in safety meetings and safety

training sessions, they would have known

that what they were doing was dangerous and

might result in an accident. Had they known,

they might have escaped injury or death.

Don't be like them! Be informed.

Now

you know. Dennis :) Now

you know. Dennis :)

|

Insight!?

Fun and useless tidbits

-

Smelling (not eating) green apples and

bananas help you to lose weight.

-

A hummingbird weighs

less than a penny.

-

Thomas

Edison was afraid of the dark.

-

Walt Disney was

afraid of mice.

-

The electric chair

was invented by a dentist.

-

Leonardo Di Vinci

invented the scissors.

-

Flies fly backwards.

-

You cannot hum while

holding your nose. (OK, tell the

truth. How many of you tried this?)

-

Apples are more

powerful than caffeine at helping to

stay awake.

-

Cat urine glows under

a black-light.

|

What Do You Know?

Don't draw a blank on safety information

Here's a quiz to test your

general safety knowledge.

- If you see a safety

hazard you can't safely fix yourself,

__________ it.

- Only use a fire

extinguisher to fight _______, contained

fires.

- The _________ on a

chemical container warns of safety and

health hazards.

- To protect workplace

security, report __________ individuals

or activities.

- _______________, such

as safety glasses and hard hats, are

personal barriers against job hazards.

- If you don't

understand a safety procedure or don't

know if something is a hazard, ask a

__________.

- A hazardous space

with limited entry and exit areas that

only trained, equipped, and authorized

personnel are allowed to enter is called

a __________ space.

- Never touch anything

electrical with _____ hands.

- When you have to lift

an object, lift with your _______

muscles.

- Places where fingers,

hands, or other body parts can get

caught between two surfaces or between

moving machine parts are known as

__________ points.

Answers at end of

Safety Bulletin.

|

|

How

to make the most of National

Preparedness Month, September 2009

This September marks the 6th Annual National

Preparedness Month sponsored by the U.S.

Department of Homeland Security's Ready

Campaign and Citizen Corps. The campaign is

designed to increase public awareness of

emergency preparedness at home, at work, and

in the community by providing free

information. The program promotes basic

steps to achieve true readiness in case of

disaster: get a kit, make a plan, be

informed, and get involved.

Get a kit:

Everyone should have an emergency kit at

home and at work with basic supplies. At

minimum, emergency kits should include:

first aid supplies, water, food,

flashlight and batteries, battery

powered or hand crank radio, and NOAA

Weather Radio. Families should be

prepared for a minimum of 72 hours

following a disaster. For a complete

supply list visit:

http://www.ready.gov/america/getakit/

Make a plan:

Planning is key to being prepared when an

emergency strikes. Plans should include how

to communicate with loved ones, where to

reunite if separated, how to decide if you

should evacuate or shelter-in-place, and

where to find the disaster kit and

additional supplies.

Be informed: Information

allows you to make decisions that will

impact how you respond to an emergency. Know

what emergencies are possible where you live

and how to effectively prepare for them.

Learn what resources are available in your

area and what emergency plans are in place

for your city, county, and state.

Get involved:

The final step promoted during Emergency

Preparedness Month is to get involved in

your community preparedness. On Ready.gov's

website groups can register to become part

of the National Preparedness Month

Coalition. Coalition members are

organizations who pledge to share

preparedness information with their

families, coworkers, customers, and

communities. In 2008, more than 3,200

organizations served as Coalition members.

Visit

http://www.ready.gov/america/npm09/members.html

to see if your group has already

registered and how you can get involved. If

your organization has not joined, consider

becoming a member to share the message of

preparedness with your community.

For more information, visit the Campaign's

Web site and toll-free numbers

(1-800-BE-READY and 1-888-SE-LISTO).

Ginny Schwartzer

is Vice President / Owner of

All Clear Emergency Management Group,

a planning and preparedness firm providing

focused emergency management services to

hospitals, healthcare facilities, schools,

universities, churches, religious

organizations, and businesses. She can

assist with your organization's plans to be

truly ready for an emergency. She can be

reached at 336-802-1800 or by

Email.

|

Wake

Up and Be Safe! Wake

Up and Be Safe!

Don't let

drowsiness cause accidents

Sleep experts say many people don't get

enough sleep. Statistics show that as many

as 40 percent of Americans say that they've

been sleepy enough during the day that it

interferes with their daily activities. And

that can have a negative impact on workplace

safety.

To counteract drowsiness on the job

and prevent accidents:

- Take a minibreak and

do some stretching exercises right at

your workstation.

- Go to the restroom

and splash cold water on your face.

- Take a walk during

your rest break to help refresh and wake

you up.

- Drink a caffeinated

beverage.

Avoid tasks that

require sharp physical or mental skills when

you're very tired. For example, operating

machinery, driving a vehicle or forklift, or

handling hazardous materials could be

dangerous if you're not fully alert.

- Be honest and don't

put yourself or others at risk.

- Switch to a less

risky task, if possible, until you feel

more awake.

- Talk with your

supervisor if you're concerned about

your abilities-or someone else's. Also

talk to your supervisor if you're taking

a medication that makes you feel drowsy

and could put you or a co-worker at

risk.

There's a direct connection

between fatigue and accidents. So keep

alert!

|

Why Organize?

Ten ways

organization helps you succeed

Why bother spending all that time

getting organized on the job?

Because being organized helps you:

-

Save time.

When you know what you're going to

do and how you're going to do it,

and when you have all the materials

and equipment you need before you

start, you won't waste time once you

get going.

-

Avoid stress.

Instead of running around looking

for the things you need and facing

all kinds of frustrations while

you're busy trying to get a job

done, you'll have everything all

lined up waiting for you when you

need it.

-

Anticipate needs,

problems, and choices.

When you organize, you're better

able to anticipate what is required

to do a job well, what problems you

might face, and what options you

might have. Instead of jumping in

blind, you'll go into the job with

your eyes open, prepared for

anything that might arise.

-

Make better

decisions. Because

you've organized and anticipated,

you'll be able to make better

decisions faster as you work.

-

Be more efficient and

productive. You

won't waste time and energy or have

to backtrack to deal with something

you forgot.

-

Make sure priorities

are met. You'll have

organized your tasks in the logical

order that allows you to meet your

priorities.

-

Handle challenges and

problems more effectively.

You'll be able to handle challenges

or problems while you work because

you'll already have the resources to

deal with unexpected events.

-

Evaluate progress.

Because you've already planned out

your work, you'll know how well

you're getting along and how much

more you have to do. That will help

you keep on schedule and finish your

work on time.

-

Meet goals.

An organized approach to your work

ensures that you will meet-or even

exceed-your goals.

-

Achieve better

results. Finally,

being organized helps you achieve

better results, which is the basis

for professional success and

personal satisfaction.

|

What Folks Are Saying...

Dennis,

Thank you so much for speaking

at our pre-outage safety

meeting. I appreciate you taking

time out of your busy schedule

to accommodate us. You delivered

a good message that was well

received by everyone. If there

is ever anything I can do to

help you, please let me know.

Thanks Again,

Jeff Lamm

Operations Manager

Roanoke Valley Energy

Weldon, NC

|

Sleep

Poll Revealing

According to a recent

Sleep in America poll by the

National Sleep Foundation, American

adults average 6.9 hours of sleep a

night. But 16 percent of those

polled said they get less than 6

hours on weeknights. And only half

the people polled thought that they

were getting enough sleep.

Twenty-four percent said that sleep

problems affected work and other

activities. Half said they often

feel tired, and 17 percent said they

feel tired every day.

Nearly one in three said they had

missed work or made mistakes because

of lack of sleep. Sixty percent of

drivers polled admitted to driving

while drowsy, and 4 percent said

they'd had an accident or near miss

because of fatigue.

One of the biggest culprits for lost

sleep was a partner's

snoring-costing an average of 49

minutes of lost sleep a night. The

poll also indicates that people with

medical conditions like arthritis

and high blood pressure sleep less

and are twice as likely to feel

tired during the day.

Weight problems are also linked to

loss of sleep. Overweight people

tend to get less sleep and feel more

tired during the day than people of

normal weight.

How do Americans prepare for sleep?

Ninety percent said they watched TV.

How do we make up for lost sleep?

More than 50 percent of the survey

group took at least one nap a week.

|

|

Answers:

(1) Report (2) Small (3) Label (4)

Suspicious (5) Personal protective

equipment (PPE) (6) Supervisor (7)

Confined (8) Wet (9) Leg (10) Pinch

|

|

About N.C. Industrial Commission

Safety Section

The N.C. Industrial Commission

Safety Education Section stands ready to

assist you with your Safety training needs.

We offer a variety of courses, designed to

suit your needs. Please give one of our

Industrial Safety Representatives a call.

DENNIS

PARNELL DENNIS

PARNELL

Director Safety Education

919-218-3000-Cell

919-807-2602

Dennis.Parnell@ic.nc.gov

KIM

NADEAU

Program Assistant

919-807-2603

919-218-9049-Cell

Kim.Nadeau@ic.nc.gov

RANDY

CRANFILL RANDY

CRANFILL

Western Carolina Area & APCAP & APW

Coordinator

919-218-2986

Randy.Cranfill@ic.nc.gov

ALVIN

SCOTT ALVIN

SCOTT

Eastern & Northeastern Areas, Eastern

Defensive Driving Instructor

919-218-2792

Alvin.Scott@ic.nc.gov

WE ARE WORKING FOR YOU!

|

|

|

|

Quick Links

General

Industry

|

|

Quick Links

Fleet Safety

Law

and condition dictate top speed

|

|

Quick Links

CENTRAL

PIEDMONT SAFETY COUNCIL

Membership

Brochure

|

|

Quick Links

EASTERN

CAROLINA SAFETY COUNCIL

Membership

Brochure

|

|

Quick Links

SOUTHEASTERN SAFETY COUNCIL

Membership

Brochure

|

|

Quick Links

WESTERN

PIEDMONT SAFETY COUNCIL

Membership

Brochure

|

|

Quick Links

MID-STATE

SAFETY COUNCIL

Membership

Brochure

|

|

Quick Links

BLUE RIDGE SAFETY COUNCIL

Membership Brochure

|

|

Quick Links

NORTHEASTERN SAFETY COUNCIL

Membership Brochure

|

|

Quick Links

WESTERN

CAROLINA SAFETY COUNCIL

Membership Brochure

|

|

Quick Links

NC RURAL WATER ASSOCIATION

|

|

Quick Links

SIGN-UP FOR OUR NCIC SAFETY

BULLETIN

Email/Newsletter

|

|

Quick Links

news & notes

SUBSTANCE ABUSE AND SAFETY

September is National Alcohol and Drug

Addiction Recovery Month.

Why talk about this? Because the majority of

Americans abusing drugs, alcohol, or both

are employed. And their abuse problem almost

always causes a safety problem.

People working under the influence of drugs

or alcohol are three times more likely to

have accidents. And they may not be the only

ones hurt. Co-workers are often injured as a

result of someone else's substance abuse on

the job.

Think about these facts:

-

Some 6.5 percent of full-time and 8.6

percent of part-time workers are current

illegal drug users.

-

Alcohol is the most widely abused drug

among working adults. An estimated 6.2

percent of adults working full time are

heavy drinkers.

-

Of 12.4 million heavy drinkers, 30.5

percent are also current illegal drug

users.

-

More than 60 percent of working

Americans know someone who has reported

for work under the influence of alcohol

or other drugs.

-

Up to 40 percent of workplace fatalities

and 47 percent of injuries are linked to

substance abuse.

Now's the time to take action

if you or someone you know has a problem.

Awareness of the problem and of treatment

options is the first step to a healthier,

safer life. The next step is getting help.

And help is just a phone call

away.Call your

NCIC AREA SAFETY CONSULTANT!

|

|

Quick Links

ARE YOU READY?

Are you ready for the next safety meeting or

safety training session?

-

Are your mind, eyes, and ears open and ready

to see, hear, and learn what you need to

know to prevent accidents, injuries, and

illnesses

-

Do you have paper and a pen so you can take

notes about points brought up during the

meeting?

-

Are you prepared to participate in the

session by asking questions, raising safety

concerns, sharing your knowledge and

experience, and giving your advice and

suggestions when appropriate?

-

Are you ready to listen to what co-workers

say about the topic being discussed and to

hear their concerns about safety?

-

Are you willing to take what you learn back

to work and use it?

If your answer to all these questions is "yes,"

then yes, you are ready.

DON'T BE AFRAID

TO ASK QUESTIONS

Sometimes people think that they're

just supposed to show up at safety meetings and

training sessions to listen, that they're not

supposed to talk. But that's not true.

Don't be afraid to ask questions if

there's anything you don't understand. And don't

hesitate to speak up if you have something

useful to contribute. Participation is an

important part of learning.

Give us a call...

|

FOCUS ON THE

FIVE S's

The Japanese have long recognized the vital

importance of being well organized on the

job. Most companies in Japan follow a simple

but rigorous program known as the Five S's,

which helps keep work areas orderly and

efficient:

-

Seiri,or sorting, refers

to the practice of sorting through all

the tools, materials, etc., in the work

area and keeping only essential items.

Everything else is stored or discarded.

This leads to fewer hazards and less

clutter to interfere with productive

work.

-

Seiton,or organizing,

focuses on the need for an orderly

workplace. Tools, equipment, and

materials must be systematically

arranged for the most efficient access.

In other words, a place for everything

and everything in its place.

-

Seiso,which means

cleaning, indicates the need to keep the

workplace clean as well as neat. At the

end of each shift, the work area is

cleaned up and everything is restored to

its place.

-

Seiketsu, or

standardizing, allows for control and

consistency. Basic housekeeping

standards apply throughout the facility.

Everyone knows his or her

responsibilities. Housekeeping duties

are part of regular work routines.

-

Shitsike, which means

sustaining, refers to maintaining

standards and keeping the work area in

an efficient and orderly state, day

after day, year after year.

|

|