|

|

|

|

||||||||||||

|

||||||||||||||

by Randy Cranfill |

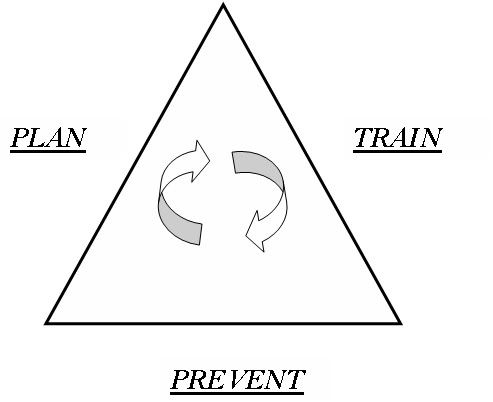

The Accident Prevention in the

Workplace “Training Plan” begins with a visit to your company by

the NC Industrial Commission Safety Education Section Safety

Representative to explain the program. The program consists of

three parts:

1.

PLAN: Involves meeting with Safety personal and/or safety

committees, review of accident history, plant tours, and picture

taking tours for hazard identification. We will develop a

suggested training plan for your workplace.

2.

TRAIN: The Safety Education Section will schedule a date

and time to train at your site.

3.

PREVENT: This is a program in action! Through the training of

hazard identification and accident prevention, the workplace can

be free of accidents, therefore reducing Workers’ Compensation

claims and costs.

ACCIDENT

PREVENTION in THE WORKPLACE

|

|||||||||||||

|

||||||||||||||

|

For example, if it goes against your religious beliefs to work

on Sunday, and other employees have to work Sundays for you, it

might be considered a hardship for the business. On the other

hand, if there are enough employees to pick up the Sunday work

and they volunteer to do so, that could be a reasonable

accommodation.

If

you are a man who wears a beard for religious reasons, and you

need to wear a respirator as part of your job, you may not get a

tight seal with the beard. If no accommodation can be made (such

as a full face mask or transfer of those job duties), safety

must come first, and you may have to choose between shaving the

beard or finding another job. While employers have a duty to

accommodate religion, you should understand that there are

certain limitations to this obligation. |

||||||||||||||

|

||||||||||||||

| by Michael Nance |

Several of you have heard me ask

during a training session if anyone checks the health inspection

rating before settling in for a meal.

About half of the folks will raise their hand.

I’ll admit that while traveling on the road, I tend to go

through drive-up windows instead of going inside to eat,

especially if I haven’t much time.

I am trying to break the habit because I want to see the

ratings for myself as one of two things I like to check out.

The other item is just how clean the restrooms are.

Let me point out here that I am

not a clean freak. I

certainly have a long way to go to claim my picture on the can

of Lysol, but I do check out the restrooms.

Why are they called “rest” rooms anyway?

Personally, I don’t rest there.

(I grew up saying bathroom.)

I’ve been told that a restroom is public while a bathroom

is private. Hmmmm, let’s move on.

If the public restroom is filthy with trash and

who-knows-what is all over the place, I am not eating there.

No telling what it’s like behind the counter in the

kitchen or grill area if they can’t keep a 8’ by 10’ area clean.

We’ve all seen the poster making it a law for employees

to wash their hands before returning to work.

Now I just mentioned about the trashed up restroom.

If the poster is in

that restroom, then employees must see the trash since it is

apparently where they wash their hands, right?

Maybe, maybe not.

A typical place to encounter the

free snacks can be at bars and taverns.

Another point here, I am not advocating alcohol, just

simply stating facts.

Bars and taverns are just as guilty to spreading

food-borne illnesses as your favorite restaurants.

Health inspectors have reported all sorts of violations,

ranging from dirty floors to lip-stained tumblers. A recent

news report had this to say:

“One North Carolina

inspector even found black-slime mold in an ice machine --

though it might not make you sick, it "would be kind of

repulsive to have in your drink," says Frances Breedlove, food

sanitation section chief for Wake County.” (taken from an

article in

SmartMoney.com by Neil Parmar).

Bloodborne Pathogens are also a

risk in these same locations.

Just suppose a person with a fresh healing wound on a

finger dips their hand deep into the bowl of peanuts.

Not only could there be a residue of bacteria but also of

blood. Not likely

you say? Okay, then

how about the person who visits the restroom, decides not to

wash up and now has bodily fluid on their hands, then dips into

the bottom of the bowl.

Now what do you think?

Sort of nasty isn’t it and I have no doubt that we have

all witnessed people that fail to wash their hands.

Perhaps at the next staff meeting

or safety meeting at your place of employment, you can simply

mention that everyone should wash their hands prior to taking a

break or eating lunch.

Just a simple and easy one-minute pitch to remind

everyone that many illnesses could be prevented by washing hands

properly. Your

fellow employees may think you’re being a little strange, but

they will most likely think about it the next time they visit

the restroom.

This might be a stretch to some

folks; washing hands properly and often can aid in accident

prevention. Not just

for personal hygiene, but for staying healthy.

Someone who is feeling ill at work isn’t as alert and

could also be taking medications leading to drowsiness

conditions. Many

products contain a warning about operating motor vehicles and

machinery while taking medications.

Washing of the hands reduces the likelihood of getting a

cold or a virus, and a bloodborne disease.

In conclusion, simple safety

precautions, such as washing the hands, can be a small part of a

good safety attitude.

If it’s been awhile since your folks have had a refresher

training class on Bloodborne Pathogens, give one of us a call.

Finally, if there isn’t a touchless hand dryer in your

place of business, please check to see if there are paper towels

and toilet tissue in each “rest” room.

Employees will appreciate it. Editor's note: Michael Nance is the NCIC Blue Ridge & Western Piedmont areas Safety Representative. If you are interested in having one of our programs in your area, please give Michael a call at 919-218-9047 or email him at nancem@ind.commerce.state.nc.us Insight

|

|||||||||||||

|

||||||||||||||

|

Log your anger. Keep track of what sets you off, so it will

be easier for you to recognize it for what it is when it

happens. Learn what makes you angry so that you can develop

strategies for containing and channeling it when it occurs.

Use empathy. When you become angry with someone, try to see the

situation from his or her point of view. This can defuse your

anger. Acknowledging that there is another point of view and

that we are all human and at times make mistakes can be a

powerful reminder to calm down.

Try a relaxation technique like deep breathing.

Remind yourself that a lot of things that people become angry

over are really not worth devoting the time and energy an angry

outburst requires.

Count to ten. Sometimes taking a quick moment to count to ten

before acting can help to defuse the anger and help you act more

rationally.

Be assertive - not aggressive. That means that you need to let

others know what your boundaries are. Try not to express

yourself when you are being overwhelmed with anger because the

chance that you will do a poor job of it is pretty high.

Regain perspective. Try to look at the situation in the big

picture and see how trivial or unimportant something really is.

Try to see that it's not worth getting worked up over, it's just

another problem that needs to be solved.

Be forgiving.

Try to let go of past hurts, slights, and resentments, and not

let them build up. This is difficult, but it can be very

freeing, and bring you peace of mind. |

||||||||||||||

|

||||||||||||||

| by Mike Bingham |

With all the

demands that are placed on our time and resources it’s often

hard just to keep up with safety duties, and even harder to get

ahead. In addition

to investigating incidents, writing reports, correcting

potential safety issues, serving on committees and teams, we

often have training and education duties to do. Scheduling

classes, reserving rooms, and gathering subject matter all take

a toll on our time and resources, and then we often need to stop

production to address safety issues or provide/attend training.

The North

Carolina Industrial Commission (NCIC) can do much of the

training work for you. We can supply instructors, subject

matter, course content, and many other resources free of charge,

at your location. Using us to do your training can free you up

to do other critical tasks that only you can do, putting your

time and safety dollars to better use.

But how about

if your company has only a few employees needing training and

you can’t meet the 15-person minimum class requirement the NCIC

has? Here’s how

teamwork and hospitality solved the problem.

Honeywell, in

Mars Hill, recently needed confined space training, but only had

5 affected employees for the class.

It would have been easy to just say, “Oh well” and move

on, but Honeywell and the NCIC teamed up to

solve the problem. The NCIC, aware that

many other companies share this problem, suggested that

Honeywell invite other area industries to attend their class.

Gordon

Randolph, Facility Manager of Honeywell, graciously hosted the

training at his Honeywell facility, making his training room

available. Mr. Randolph and the NCIC made some calls to other

businesses and the result was that 17 people from 4 different

companies who needed confined space training received it.

The resulting impromptu networking opportunity on class

day uncovered more common training needs within each company,

and we are currently scheduling additional classes together. It

also provided the NCIC with a new way to serve North Carolina’s

workers. This is teamwork in action!

If you need

training for yourself or your employees but don’t have enough

people to make the class minimum, remember that you are

not the only one with that problem.

Look up and down your street for others who share your

problem and offer up a meeting room to share with other

organizations around you.

Contact your area NCIC representative to see if he or she

knows of similar situations and can maybe help coordinate

setting up a class.

It takes a little effort, but the rewards can be great!

Here’s a

little something to think about… Alone we can do so little; together we can do so much. - Helen Keller

Editor’s Note: Mike Bingham is the Western Area

Safety Representative for the North Carolina

Industrial Commission. Mike is one of the 10 members

of the North Carolina Industrial Commission’s Safety

Department who are out there Working for You! to

make our workplaces safer and better for each and

every worker by reducing injuries to employees and

saving money for employers through education and

training.

You can

contact Mike at:

binghamm@ind.commerce.state.nc.us or call:

919.218.9045 |

|||||||||||||

|

||||||||||||||

|

Tornadoes are one of nature's most violent storms. They form

quickly, are unpredictable, and can do a large amount of damage

in a short amount of time. Usually there is very little time to

prepare or react. Do you know what to do when the tornado siren

goes off?

Tornadoes come in all shapes and sizes and can occur

anywhere in the U.S. at any time of the year. Tornadoes are most

likely to occur between 3 and 9 p.m., but have been known to

occur at all hours of the day or night. The average tornado

moves from southwest to northeast, but tornadoes have been known

to move in any direction. The average forward speed is 30 mph

but may vary from nearly stationary to 70 mph. It is a myth that

areas near water are safe from tornadoes. No place is safe.

Tornadoes have occurred on mountains, near large bodies of

water, and in downtown areas of major cities.

A

tornado watch means the

conditions are right for tornado development, but none have been

sighted. You should monitor the situation. A

tornado warning means a tornado has been sighted and there is imminent

danger for people in the warning area. You should take cover

immediately. Tornadoes develop so rapidly that advance warning

is not always possible. Know the warning signs that a tornado

may be forming or is imminent:

|

|||||||||||||

|

||||||||||||||

by Eric Johnson |

All those

flashing lights, signs, gate arms, and horns blowing are there

for a reason! Did you

know that every two hours there is a collision between an

automobile and a train or a pedestrian and a train in the United

States? Most occur

within 25 miles of our home.

At 55 miles per hour it takes a train up to one mile to

stop. Also, you are

20 times more likely to die in a collision with a train than a

collision in involving another vehicle.

In 1972, a

concerned railroad employee working with the support of many

Idaho communities established a statewide Operation Lifesaver

program. During the

first year of this program fatalities were considerably reduced.

Encouraged by these results many states followed and

today Operation Lifesaver is an international program and is

supported by state organizations as well as the railroads.

Operation

Lifesaver will give you important tips that could save your

life, and it just so happens that our safety representatives are

certified instructors.

This course was developed to reach a wide range of

audiences from general adult driver, law enforcement,

professional driver, school bus driver, high school, middle,

elementary, and kindergarten students.

There is no

charge for the course and we can tailor the class to fit your

schedule. The class

usually runs from 30 minutes to an hour.

We use a variety of methods for training from power

point, flip charts, video, and handouts to meet your audience

needs.

If your

company, school, church, civic group, drivers education class,

city, county, state organization could use this valuable

training please contact the safety representative in your area. | |||||||||||||

|

||||||||||||||

| by Michelle Morgan |

Identifying those persons who

are physically able to do the job and do not have pre-existing

conditions that may put them at risk of injury before

they begin work will not only reduce these costs by as much as

80%, but will result in a safer, more productive workforce.

Larry Feeler, CEO and founder

of Worksteps, a national employment testing company, was

recently quoted in the May 2007 issue of Joplin Business

Journal: Employers

make 3 assumptions at the outset when hiring workers:

“Workers are perfect when they are hired; workers never

grow old and what happens to the worker is your fault.

Without evidence, what can you do?”

Comprehensive post-offer employment testing provides that

evidence.

Some employers are doing

agility testing and/or medical/drug testing prior to hire.

However, employers should ask some key questions about

their current testing process:

1.

How many “non-capables” are

identified after testing?

2.

Does the testing offer a complete

(head to toe) musculoskeletal evaluation, including range of

motion, strength, posture and joint integrity assessments?

3.

Does it offer an assessment of

cardiovascular status?

4.

Does it offer a risk profile for

overuse syndromes (such as repetitive motion conditions)?

5.

Does it offer job specific or job

simulation components that include training in proper body

mechanics and lifting techniques?

6.

If an injury occurs, does the test

offer baseline information of what was there before the injury,

so that apportionment can take place?

If most of these questions are answered with a “No”, then employers should

re-evaluate their testing process.

The ADA and EEOC both say that employers have a right to

obtain medical and functional information

post offer on

an employee. Much

the same as a drug test, employees can be hired contingent on

passing the physical testing.

Without this information, the hiring process becomes

irresponsible - allowing

persons who were not safe to do the job to be hired and put

themselves as well as others at risk of injury.

Even the best safety and wellness programs will be

ineffective in reducing the likelihood of preventing an injury

if the employee cannot physically and safely perform the

physical demands of the job from day one.

Post-offer employment testing may

well be the “missing link” in safety.

Consider evaluating your employees to enhance and improve

your safety programs.

A healthy, fit workforce results in a renewed focus on

the safety and wellness of your employees.

Take care of your employees while controlling your costs.

Submitted by: Michelle Morgan,

Vice President of Job Ready Services, LLC

For more

information about post-offer employment testing or other

employer services, view Job Ready website:

www.jobreadyservices.net

or visit the Worksteps website:

www.worksteps.com.

| |||||||||||||

|

||||||||||||||

|

Correct the hazards.

In addition to rectifying equipment malfunctions, doing

equipment maintenance and training employees in proper

operation, "maintenance" is performed on workers to correct the

behavioral hazards. This maintenance can include employee

assistance and stress management programs, exercise classes, and

workshops on literacy and "locus of control" - teaching all

workers to be self-directed for their own safety. "Safety is not

[just] management's problem," says Selkirk, "safety is every

individual worker's problem." He says reducing stress and

improving morale dramatically reduces injuries.

Although these may seem like elementary measures, Selkirk says

that many companies with serious problems are not availing

themselves of any of those programs. "Companies that want to do

preventive maintenance in their equipment will spend millions of

dollars to do PMs over a period of years for sophisticated

machinery, but the most costly machinery they have is the human

worker. Yet many times they do little preventive maintenance to

make that worker more productive and loyal: by using employee

assistance programs, pre-employment screens, wellness programs,

ongoing training, we literally develop and do preventive

maintenance on an existing employee base so we get the returns

on investment of higher productivity, less absenteeism, fewer

worker injuries, fewer lawsuits and lower turnover rates."

Selkirk notes that now it's not only important to select the

right workers, it's important to take care of them "because it's

harder to get rid of them."

Instill ownership - or employee empowerment.

In a program ServiceMaster calls Passport to Safety; employees

get cash incentives to report safety hazards. In targeted

departments, names of all workers who complete a month without

work time lost to injury and attend a safety meeting are placed

in a hat for a $100 drawing. Also, 30-member teams are created

within departments, and each team that can go one quarter

without a lost-work-time injury gets to compete in a drawing for

$300.

For managers, who need motivation to work safely too, there are

incentive packages based on predetermined financial goals. But

there are also penalties for poor performance. Each workers'

comp claim can result in a $15,000 deductible being taken from a

manager's departmental budget. This proposal caused such an

uproar in ServiceMaster's management that Selkirk almost lost

his job over it. Yet, says Selkirk, "If executive management

does not tie lower management to the cost impact of loss, then

they don't manage it." It makes sense to him that if managers

get bonuses for performance, there should also be disincentives

for workers' comp claims. As far as Selkirk knows, no other

company is doing anything similar.

In measuring results of these incentive programs, ServiceMaster

has found that every $5.00 invested in incentives yields a

$95.00 average reduction in the cost of injuries.

Manage claims effectively.

If an injury occurs, managers are trained to stabilize the

worker. This might mean administering CPR or first aid or

actually escorting the injured person to receive medical

attention. Managers are also taught to call the injured worker

at home every other week, to call the doctor weekly for status

reports, and to encourage an early return to work for injured

employees by arranging for modified duty and other special

accommodations. Effective claims management measures such as

these have helped ServiceMaster to improve employee morale by

fostering a sense of caring, reduce claims costs, improve the

company's relationship with physicians, and reduce litigation

and the likelihood of fraud.

RISK MANAGEMENT WITH CONTINGENT WORKERS

Many businesses have tried to dodge risk by using contingent

workers. But if the agency placing the workers doesn't manage

them properly, observes Selkirk, no risks are truly being

shifted. If a contingent worker is injured, "not only could he

collect workers' comp from the temp agency that sends him, he

could possibly sue the company that he's working in due to a

safety issue." He notes that of the employees ServiceMaster

hires, few have filed a general liability suit against the

customer.

Selkirk says it takes one to five years to change culture so

that safe behavior becomes truly second nature or ingrained, but

that specific behaviors can be changed in one quarter through

rewards or disincentives. You know that safety has become part

of the culture when you no longer have to focus on it or use

incentives. (Beth

Rogers is a freelance writer based in Bethesda, Md.) Please give us a call for your ACCIDENT PREVENTION training. Now you know. Dennis |

||||||||||||||

|

||||||||||||||

|

Safety Education Trainer

The North

Carolina Industrial Commission Safety Education Section has

an opening for a Safety Representative in the Central

Piedmont or Southern Piedmont Region. Click

here

for a map of the territories covered by this position.

MINIMUM EDUCATION AND EXPERIENCE: Graduation from a four-year college or university and two years of experience as an Industrial Safety Representative I or three years of experience in teaching, safety work, or other fields where work requires the promotion of given ideas. (Two years of additional experience of the type mentioned above may be substituted for the college training.)

PREFERRED EDUCATION AND EXPERIENCE: Industrial Safety Training, knowledge of Microsoft Access, Excel, Word and PowerPoint.

For more

information or to apply,

http://osp.its.state.nc.us/positiondetail.asp?vacancykey=4610-0000-0010-406&printit=no

SAFETY COORDINATOR

Chemical Specialties, Inc., a chemical manufacturer, is seeking

a Safety Coordinator.

This position is responsible for performing daily

in-plant safety audits/inspections to ensure compliance with

safety programs. Lockout, hot work, permit to work and confined

space are key programs. Coordinates activities including

accident and incident reporting, training, industrial hygiene

monitoring, MSDS management, equipment calibration and

maintenance and resolution of safety action items.

Competitive pay and an exemplary benefits package.

Please visit our website at treatedwood.com or mrdc.com.

Please

send resume with salary history to:

Chemical Specialties

humanr@chemspec.com

Fax

704-455-6614

EEO-M/F/V/D-AA

City of Charlotte This position is responsible for programs/procedures to ensure OSHA compliance in Utilities Engineering and Water Treatment Divisions for employees and construction projects, ensures compliance with EPA/NCDENR Erosion Control requirements for construction. Job tasks would include safety training and

monitoring contractor and employee safety and associated

recordkeeping. Review

plans and specifications for construction projects to ensure

OSHA compliance and mitigation of hazards where possible.

Participation in EPA Risk Management Program.

Coordinate activities with other Utility Department

safety coordinators on cross-divisional safety issues and with

City of Position will serve as a compliance officer for the division’s Erosion and Sedimentation Control programs. The division currently operates under an EPA approved Erosion and Sedimentation Operation Plan. This position would monitor construction projects for compliance both in the field implementation and the required record-keeping. Requires three to five years construction safety experience and/or a bachelors degree from an accredited four year college and 1 year of construction safety experience or equivalent combination of education and experience. Authorization to conduct OSHA 500 (construction) and 501 (general industry) and other regulatory courses preferred.

|

||||||||||||||

|

||||||||||||||

|

Atlantic Beach Sheraton, September 10-14, 2007 Haven't been to the NC Industrial Commission's 30 Hour Accident Prevention Certificate Program yet? What are you waiting for? And best of all, it's FREE! Click here for more information on upcoming APCAP programs. Online registration is open now for Atlantic Beach APCAP, September 10-14, 2007. Register NOW! Here's what some of our previous participants are saying about the program: "This is a wonderful course and everyone needs to attend. " - Deborah Williams, ITG/Burlington, Salisbury APCAP "One of the best training sessions I have attended. The trainers are excellent." - Tom Lee, VA Medical Center, Salisbury APCAP "The variety of topics that were covered in this training assisted me in refreshing ideas that I can use to improve safety in my workplace." - Diane Hollar, Vantage Foods, Wilkesboro APCAP "My primary job is HR, but this class has helped me considerably with understanding safety procedures and the importance of an active written policy." - Logan Helms, City of Newton, Wilkesboro APCAP |

||||||||||||||

|

||||||||||||||

|

The NC Industrial Commission Safety Education Section stands ready to assist you with your Safety training needs. We offer a variety of courses, designed to suit your needs. Please give one of our Industrial Safety Representatives a call. Mike Bingham - binghamm@ind.commerce.state.nc.us Western Carolina Area - 919-218-9045 Randy Cranfill - cranfilr@ind.commerce.state.nc.us Central Piedmont Area - 919-218-2986 Markus Elliott - elliottm@ind.commerce.state.nc.us Southeastern Area - 919-810-5788 Mel Harmon - harmonm@ind.commerce.state.nc.us Mid-State Area and Defensive Driving Instructor - 919-218-3374 Eric Johnson - johnsone@ind.commerce.state.nc.us Southern Piedmont Area - 919-218-3567 Michael Nance - nancem@ind.commerce.state.nc.us Blue Ridge & Western Piedmont Areas - 919-218-9047 Ginny Schwartzer - schwartg@ind.commerce.state.nc.us Program Assistant - 919-807-2603 Alvin Scott - scotta@ind.commerce.state.nc.us Eastern & Northeastern Areas and Defensive Driving Instructor - 919-218-2792 Dennis Parnell - parnelld@ind.commerce.state.nc.us Director Safety Education - 919-218-3000

NC Industrial Commission |

||||||||||||||

|

|

|

|||||||||||||

|

||||||||||||||||||||||||||||||||||