|

Happy New Year Friends in the Name

of Safety:

There is no doubt we all will be

facing many challenges this year,

the economy, jobs and some type of

change.

As you struggle to seek ways to save

resources and money, remember that

the N.C. Industrial Commission is

here working for you every day. Our

staff will make every possible

effort to continue to serve you in

the fashion you have become accustom

to. Please give us a call EARLY in

order to schedule training in 2009.

We have finalized our 2009 APCAP

schedule! We are adding an ADVANCED

APCAP in 2009. In order to

participate, you must have completed

the basic 30-hour APCAP. The

ADVANCED APCAP will be two days of

intense training to further assist

you with your Safety & Health

program.

This year, we will offer BOTH

COURSES concurrently on the same

date and location in order to better

serve you.

Here are the DATES AND LOCATIONS for

2009:

-

February 9-13, 2009 -

Fayetteville, NC

-

March 9-13, 2009 -

Wilmington, NC

-

June 15-19, 2009 -

Smithfield, NC

-

August 17-21, 2009 - Flat

Rock, NC

-

August 31-September 4,

2009 - Atlantic Beach, NC

-

October 26-30, 2009 -

Asheboro Zoo, Asheboro, NC

-

November 2-6, 2009 -

Wilkesboro, NC(Not

confirmed yet)

We look forward to seeing you at

one of our programs in 2009.

Again, let us say "THANK YOU"

for allowing us to be a part of

your family.

Your

REGIONAL SAFETY COUNCILS are

continuing to work for you, so

please refer to the calendar

section of our Safety Bulletin

for more information. Please

support YOUR councils!

As always, we thank you for your

support and we pledge to

continue to serve your needs. We

promise to continue to provide

quality ACCIDENT

PREVENTION training

programs.

|

Dieting in the New

Year:Resolutions that Work!

Millions

of Americans will ring in the

New Year with health and

weight-loss-related resolutions,

but almost a third of

"resolvers" don't even see their

goals through to February. Read

on for four simple strategies to

make this year's resolution

stick: Millions

of Americans will ring in the

New Year with health and

weight-loss-related resolutions,

but almost a third of

"resolvers" don't even see their

goals through to February. Read

on for four simple strategies to

make this year's resolution

stick:

1. Consider your goal an

evolution, rather than a

resolution, since the latter

implies that if you fall off

course even once, you've failed.

2. Whenever possible, make your

goals flexible: "exercise five

hours per week" is better than

"run five hours per week"

because it can be accomplished

in many different ways.

3. Always focus on what you've

done well towards your

resolution. Rather than dwelling

on the cupcake you ate, or the

exercise you missed, give

yourself credit for packing a

healthy lunch instead of eating

drive-thru, for example.

4. Think of each day as a chance

to make healthier choices, and

give yourself a break - you

haven't failed unless you've

given up, and tomorrow is

another chance to make this

year's resolution stick.

|

|

Regional Safety Councils

Please do not forget to support

your Regional Safety Councils by

joining their membership ranks

and participating in their

scheduled events. For

membership applications, see the

Quick Links to the right.

|

Fast facts about product

dating:

Food product dating tells people

certain information about

specific foods, but there is no

uniform or universally accepted

dating system in the United

States. Except for infant

formula and some baby foods,

product dating is not required

by federal regulations. The

following definitions should

help you understand the dates

that are voluntarily printed on

food products:

Sell by: Tells the store how

long to display the product for

sale. Consumers should not buy

the product after this date.

Best if used by: Tells consumers

how long the product will retain

its best flavor or quality. This

is not a purchase or safety

date.

Use by: Tells consumers the last

date that is recommended for

using the product while at peak

quality. The manufacturer

determines this date.

Closed or coded dating:

Represents packing numbers for

use by the manufacturer to track

inventory, rotate stock, or

locate the product under

suspicion of a problem. These

dates do not indicate freshness

or quality of the product.

|

Check out our

Video Library !

Finally!

We have completed UPDATING our

online Video/DVD listings. The

new listings are in

RED.

To view the rest of our Library

and download the REQUEST FORM,

please

CLICK HERE

|

Parents' Fears NOT Unfounded

For teenagers, it's a huge

milestone, one that they've

looked forward to for years, but

for parents, it's a regular

nightmare. So what's the

occasion? It's birthday number

16 and the potential for a

driver's license. With promises

of freedom and new

responsibility, it's no wonder

15-year-olds are spotted holding

their breath as their 16th

birthday approaches.

But it's also no wonder that

parents are terrified - they

actually have good reason to be.

Not surprisingly, new drivers

have the highest crash risk of

any age group. In 2004, of all

fatal crashes in 2004 that

involved 16-year-old drivers,

driver error and speeding were

involved in 78 and 39 percent of

them (respectively). Nighttime

driving is even more dangerous

for beginners - and the fatal

crash rate is twice as high as

it is during the day.

Luckily, there are things that

parents and teens can do to

ensure that, as new drivers,

teens are as safe as they can

be.

- Don't rely solely on a

driver's education program to

teach a teen to drive. While

this is a good starting point,

it's also smart to make sure

you're comfortable with how your

teen acts behind the wheel.

- Don't expect that your teen is

as comfortable driving at night

as he/she is during the day.

Some students in driver's

education programs never gain

any experience driving in the

dark.

- Restrict the number of

passengers your teen is allowed

to have in the car. Not only can

passengers be a distraction, but

new drivers may feel compelled

to take risks they normally

wouldn't take when driving

alone.

- Require seatbelt use at all

times, remembering that a teen's

habits may change when a parent

or guardian is not in the car.

- Understand and support

graduated licensing programs in

your state. If your state

doesn't have one, you might

consider implementing one of

your own, allowing your teen

increased responsibility over

time.

|

|

Second Nature

By Michael Nance

As I sat down to think about an

article for the January 09 edition

of our world renowned newsletter, I

found myself thinking about the

situations I've been in and what I

either did right or wrong with

regard to safe work practices. Even

though just a few things resulted in

an incident with minor injury, all

of them were preventable. Well,

with the exception of one and I will

let you be the judge on that.

You have heard the phrase, "When it

rains, it pours" (which was made

famous by the Morton Salt Company).

Beginning the Friday prior to

Thanksgiving is when the flood gates

opened up. Just as my day was

getting started with work, my car

was rear-ended by another motorist

with an estimated 30-35 mph

impact. Everything, and I mean

everything, ended up in the back

seat area. Coffee, notes/papers,

sunglasses and even the garage

remote opener that was firmly

clipped to my sun visor landed in

places I did not know existed in the

car. Fortunately, I did not require

an expensive ambulance ride to the

hospital and neither did the other

party. It did, however, take five

weeks to get my car back.

Preventable? Yes. The other party

simply was not paying attention.

Two weeks later on a Saturday night,

my wife slipped on the bottom step

of the staircase carrying gifts to

wrap. She fell and then let the

rest of the family know about it.

She was in pain and thought she had

broken her right ankle. I

remembered the RICE acronym:

R-Rest, I-Ice, C-Compression, and

E-Elevation. With a little movement

I could tell she did not have a

fracture, but three hours later she

decided to go get x-rays just in

case. Nothing more than a serious

sprain, though a lot of discomfort.

Something that she is still

recovering from as I type.

Preventable? Yes. She didn't have a

clear view of the steps (she'll

break my neck after reading this).

Three hours after we got home from

the Urgent Care, I was working on a

Christmas gift for my wife. I had

purchased a hand blown ornament from

the Blue Ridge Parkway Foundation

store and was making a holder for it

out of wood and copper. I decided

the piece of wood needed to be

trimmed down and drug out my bench

top 6" wood jointer. Properly

plugged in, safety glasses on,

gloves on, push blocks in

use,....still two fingers found

their way into a spinning blade as

the wood ripped out of my gloved

hand along with the push blocks. I

was doing everything I thought to be

correct, following all the required

safety precautions and still got

hurt. I shudder to think that I may

have lost the tip of a finger.

Fortunately, the gloves jammed the

blades as I jerked my hand back. I

only gouged out a chunk. Luckily, it

is almost healed. Preventable?

You be the judge.

Let's see,...another 3 hours passed

and my son got an upset stomach and

really caused a stink,.....well, no

need in getting graphic. About five

more hours passed and my daughter

woke up in the middle of the night

and started talking about how she

"didn't feel" well. I've heard the

whine before and as I was thinking

she was "acting", she hurls on the

bedroom floor. Again, no need to

get graphic here either. Was either

of these preventable? Yes. Too

many sausage balls too fast will

make you sick!

In a 12 hour time span, the Nance

family could have experienced four

Urgent Care visits, even though my

wife was the only one who actually

went. Wow,...that would have been

$200 in co-pays! As I now reflect

on these events, and just a few

others that happened in 2008, I feel

good that I have learned from my

association with other safety

professionals in how to prevent

accidents. Yes, I had some

incidents, but the training I have

received over the years helped me

deal with it and do the right

thing. Five years ago, I would not

have instantly thought of "RICE".

Ten years ago, I would not have

really cared if I had safety glasses

or gloves on when using a

woodworking tool. In 2008, it was

second nature.

Let me ask again,....was the

incident with the finger in the wood

jointer preventable? After all I

was using all required PPE, all

machine guards in place and working,

push blocks in use, etc. A really

good friend of mine introduced me to

three famous safety words a few

weeks after we met (you know who you

are)! Those words were: Speed,

Ease, and Comfort. In honest review

of the "you be the judge" incident,

I left out one key ingredient in the

mix. It is one of the "three

words"....speed. I was probably

feeding the wood too fast into the

cutter blade,....and zap. Safety

jumped up and bit the daylights out

of my finger. I will forever have a

reminder scar.

Let all of us be reminded and honest

with ourselves in 2009 and make

safety "second nature"

Editor's note: Michael Nance is the

NCIC Blue Ridge, Southern & Western

Piedmont areas Safety

Representative. If you are

interested in having one of our

programs in your area, please give

Michael a call at 919-218-9047 or

email him at

Michael.Nance@ic.nc.gov |

|

Hidden Problem Could Help Silent

Killer

By Mike Bingham

Your

carbon monoxide detector could

assist a silent killer. Some carbon

monoxide detectors have a life span

of only two years. Check yours now

and come back to read the rest of

this article. Your

carbon monoxide detector could

assist a silent killer. Some carbon

monoxide detectors have a life span

of only two years. Check yours now

and come back to read the rest of

this article.

I've already delivered my point

above, but read on for a review of

carbon monoxide and maybe some

lesser known facts about it.

It seems strange sometimes how one

thing leads to another once a

subject comes up. I recently had

cause to bone up on carbon monoxide

(CO) for a class that had been

requested. The more I read about it

the more interesting it became. The

old cliché of carbon monoxide being

the silent killer has roots in

reality; CO is a poisonous,

tasteless, odorless, invisible gas.

Signs and symptoms include headache,

nausea, fatigue, dizziness,

drowsiness, chest pain, confusion,

muscle weakness, loss of

consciousness, and death. Carbon

monoxide can have a cumulative

effect. Small daily doses can

accumulate into potentially deadly

doses over time.

One carbon dioxide MSDS I downloaded

gave an HMIS Health rating of 1. As

we know, 1 represents a slight

hazard, and 4 is the most severe

hazard. Why is this deadly gas

given a 1? In this case it is

assumed that the product is used as

intended with all safety measures,

safeguards, and training in place.

If the safeguards aren't in placed

or aren't used, all bets are off.

One of the common uses of carbon

monoxide is as a fuel. The safety

geek in me got all upset and wanted

to know why, if it is used as a

fuel, it kills people who are

exposed to it due to fire or engine

exhaust. We already know that CO is

produced during incomplete

combustion. A little research

showed that CO has an ignition

temperature of 609 degrees C / 1128

degrees F. So, if the original fuel

burns at a lower temperature than

CO, the CO survives as a deadly

byproduct of the fire.

According to the numerous sources,

carbon monoxide poisoning is the

most common cause of accidental

poisoning deaths in the United

States every year. Most of these

deaths are preventable with proper

education and training, and a few

other basic measures.

First, determine whether you need a

CO detector. If you have dependable

electric heat in your home, and will

never use a combustion-based backup

heater or appliance, you won't

really need a CO detector. If you

have all electric forklifts in your

workplace, likewise, you won't need

a CO detector to protect employees

from them. Gas heat or appliances

in the home or workplace or working

around fossil fuel powered forklifts

could trigger different needs and

necessitate installing detectors.

If you get a CO detector, READ THE

OWNER'S MANUAL WORD BY WORD. It

will tell you the specific type of

battery required in some cases. It

will tell you how high to mount the

detector from the floor. CO is

slightly lighter than air, and since

it accompanies combustion, and hot

air rises, the detector needs to be

mounted at prescribed heights - see

the owner's manual for this.

Preventing poisoning by carbon

monoxide includes having preventive

maintenance tasks in place to keep

all equipment capable of producing

it in top working order. If you

lack the tools and expertise to

service the equipment, hire a

professional to do it. Be sure to

test the CO detector and replace the

battery as recommended by its

manufacturer.

Carbon monoxide detectors are simply

tools. They are designed for a

specific job - detecting CO. They

should not take the place of smoke

detectors and vice versa. There are

combination units available, but be

sure you are aware of the CO

detector's life span. As with any

good tool, it needs to be used for

the right purpose. It needs to be

maintained, and its functionality

verified. And it has to be

understood.

Editor's Note:

Mike Bingham is the Western Area

Safety Representative for the NCIC,

and one of the 10 members of the

NCIC's Safety Department who are out

there

Working for You!!!to make

N.C. workplaces safer and better by

reducing injuries to employees and

saving money for employers through

education and training. You can

contact Mike at:

mike.bingham@ic.nc.us or call:

919.218.9045

|

From the Desk of

Dennis Parnell

Director Safety Education

January is a good time...

...Take a look at your personal

priorities. With the new year ahead

of you, and the holidays behind, it

might be a good time to look at your

priorities, at work and at home.

Your employer values your hard

work. You do your best to exceed

his or her expectations. You may

have even been rewarded for your

efforts with a promotion or an

increase in your compensation.

Working longer hours than necessary,

even working weekends has become

your "normal" work practice. But is

it too much? Are you out of

balance?

Work is very important, but you need

to take a look at whether or not you

are working too much for your own

good, which is ultimately a

problem. As you place more and more

demands on yourself, you are less

and less likely to realize that this

stress is affecting you. Everyone

has a breaking point; do you know

where yours is?

There might be a need for you to

re-evaluate and make some changes in

your work and personal life

priorities. Ask yourself whether or

not these situations apply to you:

- Taking time off from work seems

difficult, if not impossible.

- You find it hard to relax at home.

- You miss family activities because

you think you need to work.

- Your expectations of yourself are

greater than anybody else's.

- You feel pressured about getting

everything done that "needs" to be

done.

- You have a nagging sense that

failing would be the worst thing

that could happen to you.

If you see yourself in any of these

situations, it is time to take a

long, hard look at your priorities.

Self-induced stress is often

difficult to recognize. A healthy

balance between your working life

and your personal life will lead to

a more satisfying life in the long

run. Get help today if you need it.

Now you know. Dennis :) |

|

Insight!

Fun and useless tidbits

There is only one Q in a Scrabble

game.

The only wood used by famed London

cabinetmaker Thomas Chippendale was

mahogany.

The pecan tree is the only naturally

growing nut tree in North American.

It is native to the Texas,

Mississippi and Mexico River

Valleys.

The only rock that floats in water

is pumice.

The Virginia opossum is the only

marsupial (pouched mammal)

indigenous to North America.

Average length of a coat hanger when

straightened: 44 inches.

Average number of eggs laid by the

female American Oyster per year: 500

million. Usually only one oyster out

of the bunch reaches maturity.

Average calories burned daily by the

sled dogs running in Alaska's annual

Iditarod race: 10,000.

An ear of corn averages 800 kernels

in 16 rows.

|

|

Savers Credit: A Special Tax Break

The IRS wants low- and

moderate-income workers to know

about a special tax break called the

Saver's Credit. Workers who

contribute to an IRA, a 401(k) plan,

403(b) plan, governmental 457 plan,

and other retirement programs may be

eligible for this tax break. It is

definitely something you should

investigate!

The Saver's Credit can be claimed

by:

-

Married couples filing

jointly with incomes up to

$53,000 in 2008; $55,500 in

2009;

-

Heads of Household with

incomes up to $39,750 in

2008; $41,625 in 2009; and

-

Married individuals filing

separately and singles with

incomes up to $26,500 in

2008; $27,750 in 2009.

This credit can increase a

taxpayer's refund or reduce the tax

owed. The maximum saver's credit is

$1,000, or $2,000 for married

couples. However, the credit is a

percentage of the qualifying

contribution amount, with the

highest rate for taxpayers having

the least income.

Other restrictions apply:

-

Employee must be 18 years or

older;

-

Employee cannot be claimed

as a dependent on someone

else's return;

-

Employees who are students

are not eligible; and

-

Certain retirement plan

distributions reduce the

contribution amount used to

figure the credit.

If your employer offers a 401(k) or

you have an IRA, you may benefit

from the Saver's Credit. Employees

have until April 15, 2009, to set up

a new individual retirement (IRA) or

add money to an existing IRA to get

credit for 2008. However, only

elective deferrals made to workplace

retirement plans prior to December

31, 2008, are eligible for the 2008

credit.

|

NFPA

releases 2009 Edition of NFPA

70E® NFPA

releases 2009 Edition of NFPA

70E®

By W. Jon Wallace, CSP, MBA:

Workplace Group

The National Fire Protection

Association (NFPA) issued the

revised 2009 edition of NFPA 70E®:

Standard for Electrical Safety in

the Workplace with an effective date

of September 5, 2008. The 2009

edition of NFPA 70E® contains

numerous revisions. Listed below is

a summary of the major changes:

Contractor Relationships: Article

110.5 requires host employers inform

contractors of known hazards covered

by NFPA 70E® related to the contract

employer's work. The contract

employer shall ensure that each of

his/her employees is instructed in

the hazards provided by the

employer.

Training Requirements - Emergency

Procedures: Article 110.6 requires

employees exposed to shock hazards

that are not reduced to a safe level

by applicable electrical

installation requirements be trained

in approved methods of

resuscitation, including

cardiopulmonary resuscitation (CPR).

The training shall be certified

annually by the employer.

Electrical Safety Program Audit:

Article 110.7 requires the written

electrical safety program be audited

on a frequency established by the

employer.

Arc Flash Hazard Analysis: Article

130.3 requires the arc flash hazard

analysis be updated whenever a major

modification or renovation takes

place. In addition, the analysis

shall be reviewed periodically, not

to exceed five years.

Arc Flash Protection Boundary: The

criteria for the 4 feet arc flash

protection boundary for voltage

levels between 50 and 600 volts has

been modified based on upstream

protection device clearing time of

maximum 2 cycles (0.033 seconds) and

available bolted fault current of 50

kA or any combination not exceeding

100 kA cycles.

Equipment Labeling: Article 130.3

(C) states equipment shall be field

marked with a label containing the

available incident energy or

required level of PPE.

Selection of Personal Protective

Equipment: Article 130.7 contains

several revisions with respect to

arc flash PPE requirements. For

example: Table 130.7 (C)(9) has been

expanded to include additional job

tasks such as performing infrared

thermography as well as other

non-contact inspections outside the

restricted approach boundary.

Additional categories of equipment,

such as arc-resistant switchgear,

have been added to the revised

table. Also, Table 130.7 (C)(10) has

been revised and placed an a more

user-friendly format.

Annex Revisions: The following

annexes have been significantly

revised - Annex F (Hazard/Risk

Evaluation Procedure); Annex H

(Simplified, Two-Category,

Flame-Resistant [FR] Clothing

System.)

Please remember this article is

intended as an overview and not a

comprehensive summary of changes to

the 2009 edition of NFPA 70E®. For

more information on electrical safe

work practices

CLICK HERE for our

January 21, 2009

course at RTP.

If you have any questions concerning

this article or other safety issues,

please contact W. Jon Wallace at

919.933.5548 or e-mail at

jwallace@workplacegroup.net. |

|

Mulling

it over could cost you your life! Mulling

it over could cost you your life!

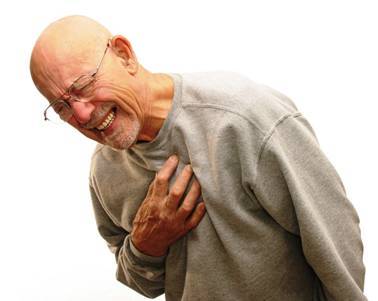

A heart attack is a terrifying

event, and most people assume that

they are dramatic, intense, and

sudden, and while they can be all of

these things, heart attacks are much

more likely to come on slowly,

sometimes causing only mild pain and

discomfort at first.

Unfortunately, misconceptions about

what heart attacks feel like can

prevent people from realizing what

is going on and getting immediate

help. Signs of a heart attack

include:

- Chest discomfort - Could be in the

form of pressure, a squeezing, or

pain that lasts more than a few

minutes. Such pain could stop and

start - don't disregard pain just

because it stops temporarily.

- Pain or discomfort in the upper

body - Can include one or both arms,

the back, neck, jaw, or stomach.

- Shortness of breath - May or may

not be accompanied by other

symptoms.

- Other symptoms - Victims might

also break into a cold sweat or

experience nausea or lightheadedness

during a heart attack.

A heart attack sufferer might not

look anything like the

chest-clutching victim often seen in

the movies, but that doesn't mean

that more subtle symptoms are any

less serious.

Few people are likely to know with

certainty that the symptoms they are

experiencing are associated with a

heart attack, but the fact is that

1.1 million Americans suffer heart

attacks each year.

Being too embarrassed to seek help

or unsure about symptoms are two

good ways to keep from getting the

treatment that could potentially

save your life, or the life of

someone you love. Even if symptoms

seem mild, it's imperative that you

seek medical attention immediately -

treatment is most effective if

administered within one hour of the

onset of symptoms.

|

|

When to replace your...

By: Eric Johnson

There's a good chance that you hold

onto certain household items far too

long. It might be because you're

trying to limit waste, because

you're attached to your things, or

because you don't realize some items

should be replaced. While you might

claim to be too busy (or too cheap!)

to replace them, your safety,

health, and hygiene might just

demand that you consider replacing

the following items much more

regularly than you do:

Your toothbrush - The

American Dental Association

recommends that you replace your

toothbrush every three to four

months or sooner if it becomes

visibly worn (the bristles are

frayed or falling out, for example).

It's also a good idea to get a new

toothbrush after you've been ill.

Your pillows - Pillows

trap bacteria, odor, and dust mites

over time. It's a good idea to

preplace your pillows every year.

Your mattress - The

National Sleep Foundation says that

a good mattress can last up to ten

years, so you should at least

replace yours that often. However,

if you typically don't sleep well,

you may find benefits from replacing

your mattress more often (e.g.,

every five to seven years).

Your contact case -

Contact lens wearers are more

susceptible to eye infections than

non-wearers. Properly caring for

your contact lenses and replacing

your lens case every three to six

months can help limit such

infections.

Your tires - Of course,

tire wear depends on many factors,

the most significant of which is how

much you drive. Try inserting a

penny into the tread of your tire.

If you can still see all of

Lincoln's head, the tread isn't very

deep, and it's probably time to

replace your tires.

Your smoke detectors -

You've probably heard that you

should change the batteries in your

smoke detectors at least once each

year, but you should also replace

the smoke detectors themselves every

eight to ten years.

Your fire extinguisher -

Fire extinguishers may lose pressure

over time; it's best to replace them

every ten years.

Eric Johnson is the Mid-State Safety

Representative and Water/Wastewater

Coordinator and covers a fourteen

county area around Raleigh. Please

call 919-218-3567 to schedule

training.

|

|

|

About N.C. Industrial Commission

Safety Section

The N.C. Industrial Commission

Safety Education Section stands

ready to assist you with your Safety

training needs. We offer a variety

of courses, designed to suit your

needs. Please give one of our

Industrial Safety Representatives a

call.

DENNIS

PARNELL DENNIS

PARNELL

Director Safety Education

919-218-3000-Cell

Dennis.Parnell@ic.nc.gov

KIM

NADEAU KIM

NADEAU

Program Assistant

919-807-2603

Kim.Nadeau@ic.nc.gov

RANDY

CRANFILL RANDY

CRANFILL

APCAP & APW Coordinator

919-218-2986

Randy.Cranfill@ic.nc.gov

ALVIN

SCOTT ALVIN

SCOTT

Eastern & Northeastern Areas,

Eastern Defensive Driving Instructor

919-218-2792

Alvin.Scott@ic.nc.gov

WE ARE WORKING FOR YOU! |

|

|

CENTRAL PIEDMONT SAFETY COUNCIL

|

EASTERN CAROLINA SAFETY COUNCIL

|

SOUTHEASTERN SAFETY COUNCIL

|

WESTERN PIEDMONT SAFETY COUNCIL

Membership Brochure

|

BLUE RIDGE SAFETY COUNCIL

|

NORTHEASTERN SAFETY COUNCIL

|

WESTERN CAROLINA SAFETY COUNCIL

|

NC RURAL WATER ASSOCIATION

|

|

Peace at Work,

a non-profit dedicated to violence

prevention, in and

through, the workplace believes that

prevention is best way to have a

safe

and secure workplace. Johnny Lee,

the founder and director, is the

author

of Addressing Domestic Violence at

Work and was previously the

Workplace

Violence Specialist for the NC

Office of State Personnel.

Conference

presentations have been provided for

organizations such as the NC

Industrial

Commission, ASSE, NC Safety Council,

Society of Human Resource Managers

and ASIS.

Right now, he is offering a free

trial of an electronic panic button

that

can send summon help with just a tap

of your keyboard, mouse or foot.

More info can be found by

CLICKING

HERE

|

SIGN-UP FOR OUR NCIC SAFETY BULLETIN

Email/Newsletter

|

|

![]()

![]()